Magbot launches wireless Automatic Tool Changer for robots

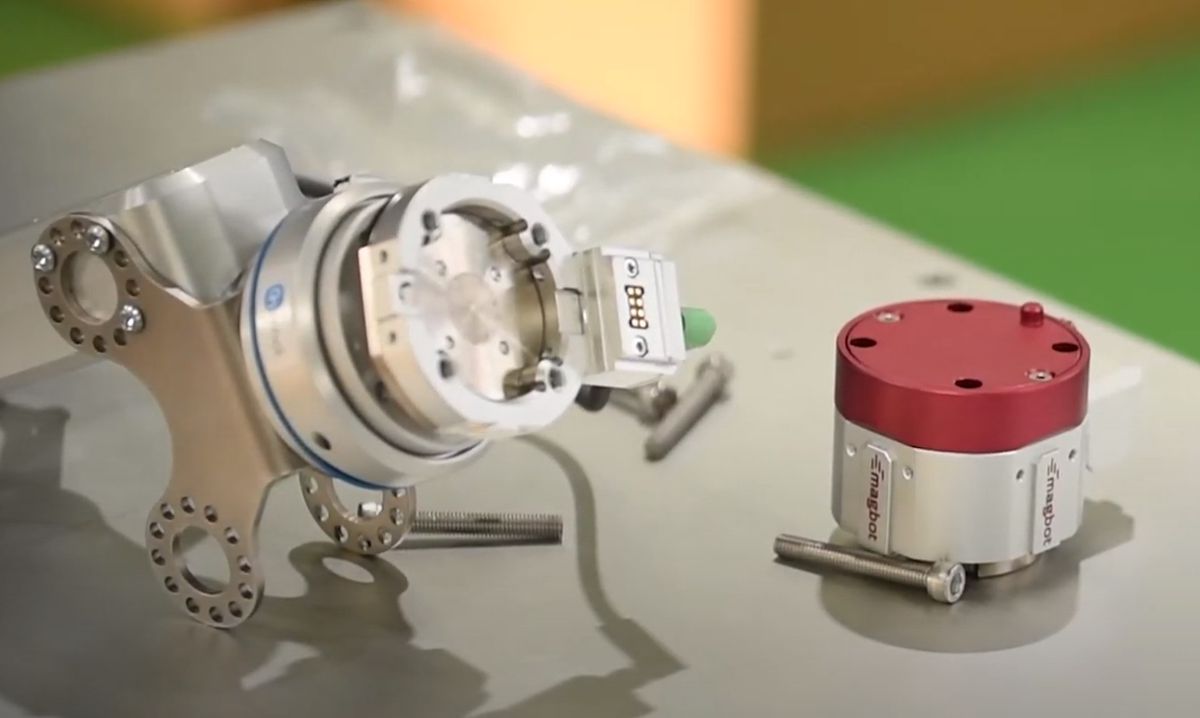

The Magbot ATC (Automatic Tool Changer) is the world’s first completely wireless Robot automatic tool changing system.

A single robot requires various robot end-effectors (tools) to provide the multi-processes and services, thus a robot ATC is essential to change the tools automatically. Without robot ATC, you have to stop the robot and change the tool. It is really inefficient and lower productivity.

Magbot ATC offers an ultra-simple robot automatic tool changing system based on an ultra-fast, ultra-powerful patented switching magnetic technology.

All the other ATC suppliers use the ball locking/unlicking mechanical process with a pneumatic system, which must have complicated pneumatic cables powered by an air-compressor. Robot ATC is a structure in which a master (male/tool changer) and a slave (female/tool plate) are combined, so competing tool plates are inevitably expensive, because of ball locking structure, which is roadblock to efficient operation.

Magbot ATC requires no pneumatic lines, or external power at all. Also, the tool plate is a very simple structure, so expansion with various tools for automated and unmanned robot system ensures scalability.

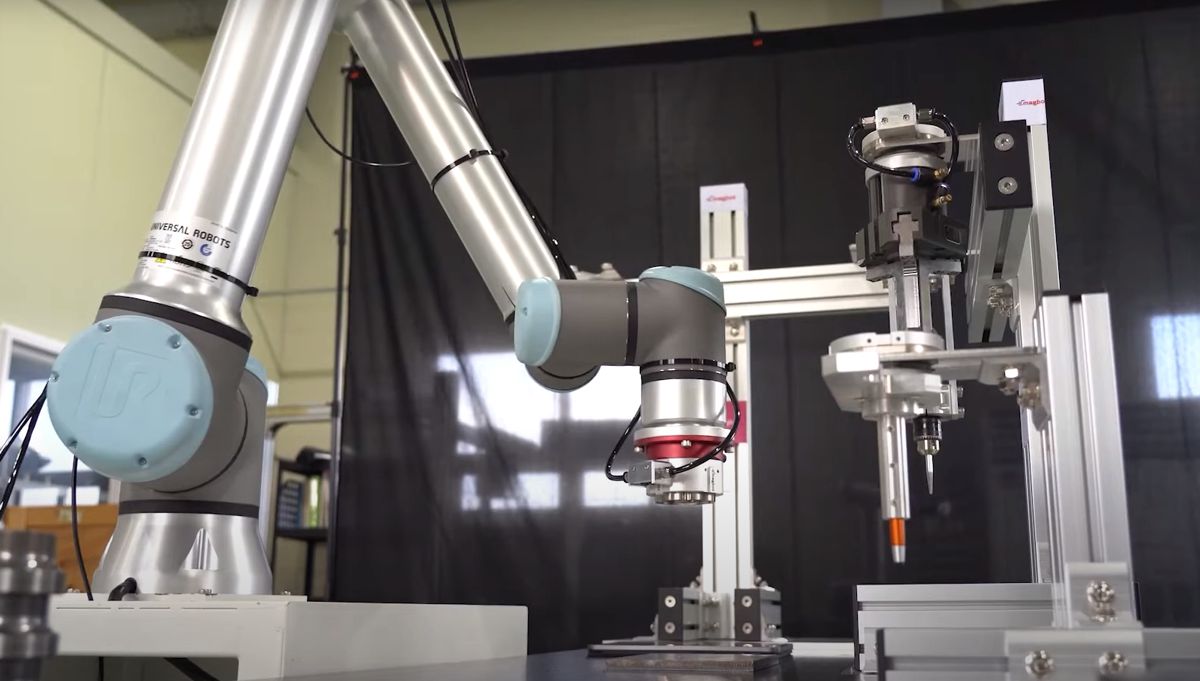

The Magbot ATC series has been certified UR+ from Universal Robot, the world No.1 Cobot maker.

Along with the world’s first fully wireless automatic tool changer of TCW1, the wired automatic tool changer of TCV1 with a payload of 10Kg and TCV2 with a payload of 16Kg are ultra-simple operating system by using the robot’s internal power system(24V@2) without any external power or pneumatics.

Magbot also provides innovative value to customers by expanding the application to the Magnetic Gripper for the pick and place process, in addition to the robot ATC function.