New materials developed in South Korea help Air Taxis take off

Development of 100% self-reinforced composites for urban air mobility (UAM) and other applications. Significant improvement in bonding strength, tensile strength, and impact resistance compared to previous work.

In order for future mobility, such as urban air mobility (UAM), to become a reality, it must be fuel efficient and reduce carbon emissions, which requires the development of new materials with excellent physical properties and recyclability.

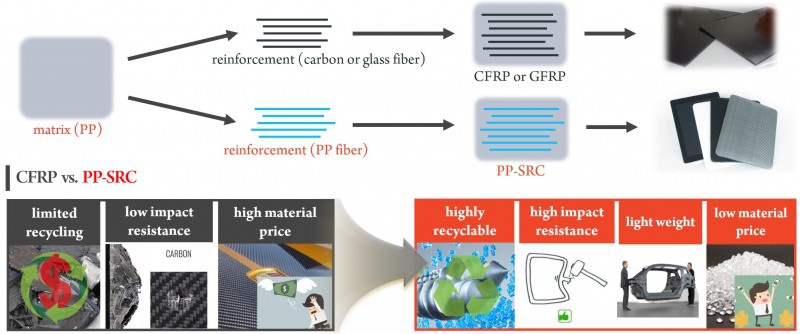

Self-reinforced composites (SRCs) are inexpensive, lightweight, and have advantages in terms of disposal and recycling as the reinforcement and the base material are composed of the same material.

For this reason, it is attracting attention as a next-generation composite material to replace carbon fiber-reinforced composites used in aircraft.

Korea Institute of Science and Technology (KIST, President Seok Jin Yoon) announced that Dr. Jaewoo Kim of the Solutions to Electromagnetic Interference in Future-mobility(SEIF), together with Prof. Seonghoon Kim of Hanyang University and Prof. O-bong Yang of Jeonbuk National University has successfully developed a 100% SRC using only one type of polypropylene (PP) polymer.

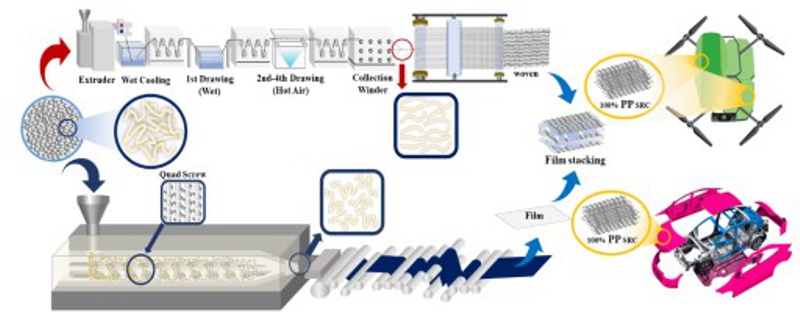

Until now, in the manufacturing process of SRCs, chemically different components have been mixed in the reinforcement or matrix to improve fluidity and impregnation, resulting in poor physical properties and recyclability. The research team succeeded in controlling the melting point, fluidity, and impregnation by adjusting the chain structure of the polypropylene matrix through a four-axis extrusion process.

The developed SRCs achieved the highest level of mechanical properties, with adhesion strength, tensile strength, and impact resistance improved by 333%, 228%, and 2,700%, respectively, compared to previous studies.

When applied as a frame material for a small drone, the material was 52% lighter than conventional carbon fibre reinforced composites and the flight time increased by 27%, confirming its potential for next-generation mobility applications.

Dr. Kim of KIST, said: “The engineering process for 100% SRCs developed in this study can be immediately applied to industry, and we will continue to work with the joint research team and industries to secure the global competitiveness of magnetically reinforced composites.”