Spot gets an upgrade with self-charging, remote operation and an arm

Boston Dynamics, the global leader in mobile robotics, today announced an expanded product line for its agile mobile robot Spot.

The new products include a self-charging Enterprise Spot, web-based remote operations software, Scout, and the Spot Arm. These additions extend Spot’s ability to perform autonomous, remote inspections and data collection, and enable the robot to perform manual tasks.

With more than 400 Spots out in the world, the robot has successfully undertaken hazardous tasks in a variety of inhospitable environments such as nuclear plants, offshore oil fields, construction sites, and mines. Customers have leveraged Spot’s advanced mobility, autonomy, control, and customizability to improve operational efficiency, enhance worker safety, and gather critical data. Spot’s new products are designed to enable customers to fully operationalize continuous, autonomous data collection on remote or hazardous worksites of any size, from anywhere they have access to their network.

Autonomy is critical to enhancing Spot’s value. In order to support long, remote deployments, Boston Dynamics is introducing Spot Enterprise, a new version of Spot that comes equipped with self-charging capabilities and a dock, allowing it to perform longer inspection tasks and data collection missions with little to no human interaction. In addition to the basic capabilities that the base Spot robot offers, Spot Enterprise leverages upgraded hardware for improved safety, communications, and behaviour in remote environments. These upgrades expand the range that autonomous missions can cover, extend WIFI support, add flexibility to Spot’s payload ports, and enable users to quickly offload large data sets collected during the robot’s mission.

Pivotal to refining Spot’s value at scale is remote operation. Scout is Boston Dynamics’ web-based software that enables operators to control their fleet of Spots from a virtual control room. Operators can use Scout to take Spot anywhere a person could go on-site, allowing them to inspect critical equipment or hazardous areas from afar. The software is designed with a simple user interface to run pre-programmed autonomous missions or manually control the robot, to perform various tasks such as walking or posing the robot to capture images and thermal data of obscured gauges or pipes using the Spot CAM+IR thermal imaging payload.

Combined, the Spot Enterprise robot equipped with a Spot CAM+IR thermal imaging payload, Scout software, and Boston Dynamics’ premium support now create an out-of-the-box solution for asset-intensive environments. Operators can deploy this solution on site to proactively maintain and manage assets while maximizing worker uptime and improving worker safety.

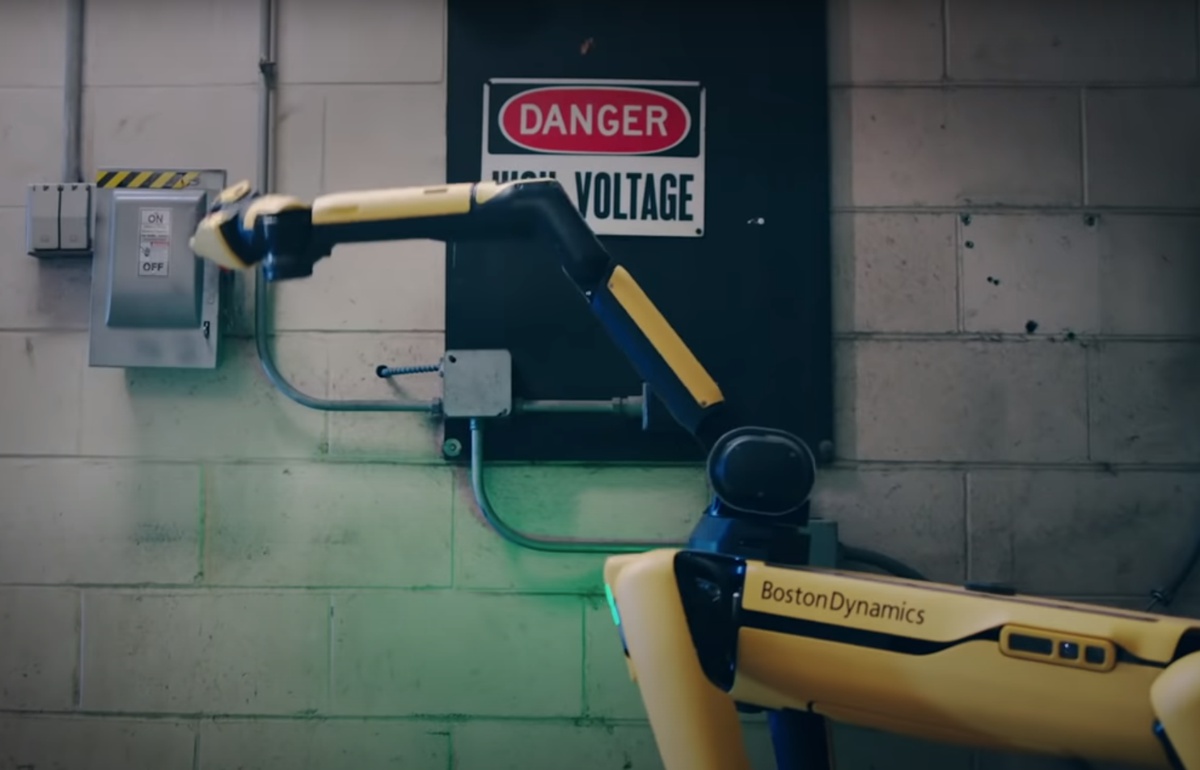

In addition to launching products designed to make remote inspection safer and easier, Boston Dynamics is also releasing the Spot Arm, which enables users to act on data insights and perform physical work in human-centric environments. The arm is equipped to operate through both semi-autonomous actions and telemanipulation. It can manually or semi-autonomously grasp, lift, carry, place, and drag a wide variety of objects. It is also capable of manipulating objects with constrained movement and can open and close valves, pull levers and turn handles and knobs in coordination with its body to open standard push and pull doors.

“Since first launching Spot, we have worked closely with our customers to identify how the robot could best support their mission critical applications,” said Robert Playter, CEO of Boston Dynamics. “Our customers want reliable data collection in remote, hazardous, and dynamic worksites. We developed the new Spot products with these needs in mind, and with the goal of making it easy to regularly and remotely perform critical inspections, improving safety and operations.”