3D Collision Avoidance goes plug and play with new Toposens Processing Unit DK

The Munich-based high-tech start-up has released its plug and play solution “Toposens Processing Unit DK” as a gateway between Toposens 3D Ultrasonic Sensors and customer applications.

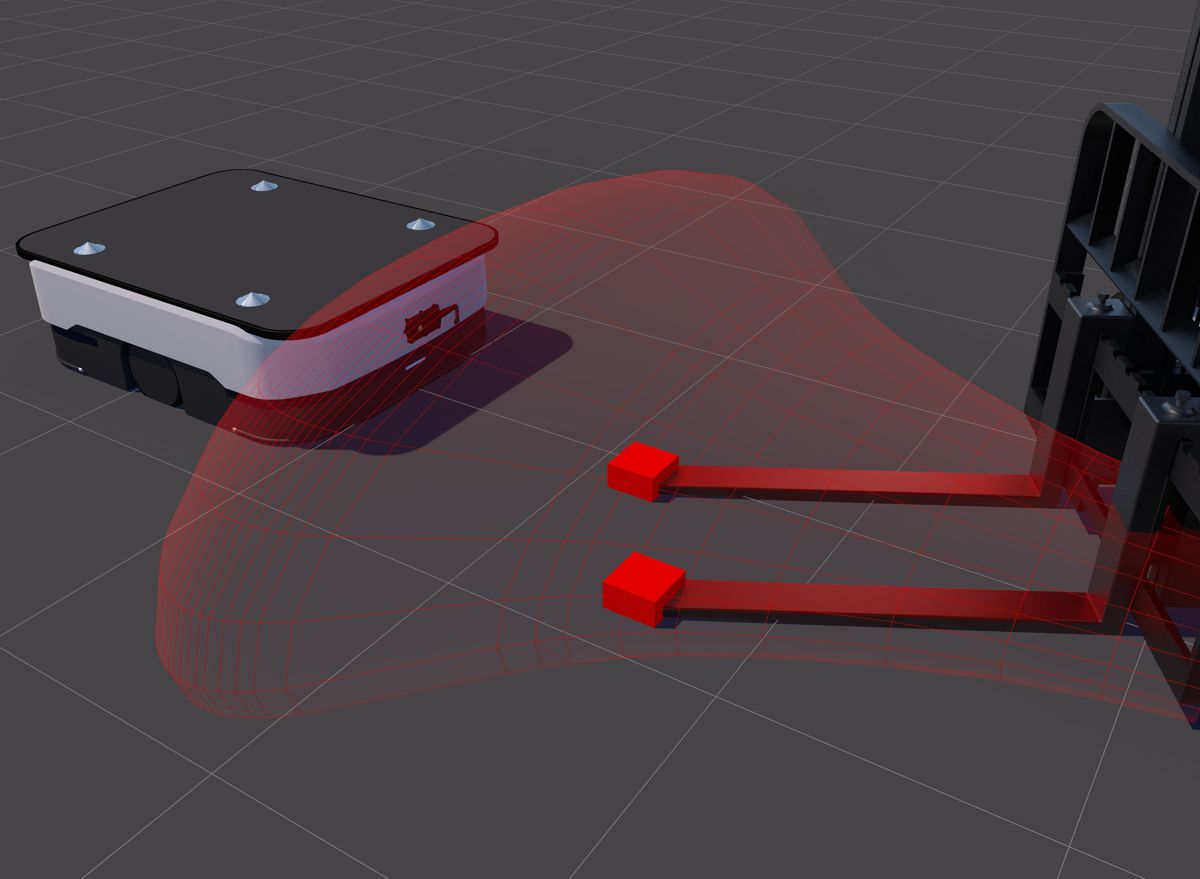

The Toposens Processing Unit DK makes it even easier to integrate the Toposens ultrasonic sensing technology into a customer’s existing platform to evaluate 3D collision avoidance. It interconnects the Toposens 3D Ultrasonic Echolocation Sensor “ECHO ONE DK” to an AGV or AMR infrastructure, enabling AGVs and AMRs to avoid collisions with all kinds of obstacles.

The TPU DK features advanced data processing algorithms which are used to communicate to an AGV’s or AMR’s control system via standardized outputs, whether an obstacle violates the user-configurable warning and stop zones.

This takes away the hassle of complicated integration procedures. The user-friendly graphical user interface (GUI) visualizes the adjustable 3D warning zones and stop zones, which are configurable to suit different use cases.

Individual sensor parameters can also be adjusted in the GUI together with the sensor vehicle positioning.

Alternatively the sensor also offers a “fusion mode,” where the TPU DK delivers pre-filtered point cloud data to another processing device via ethernet.

“Toposens Processing Unit DK is the combination of Toposens ECHO ONE DK and Toposens Processing Unit DK, which provides our customers with an unprecedented 3D Ultrasonic Collision Avoidance for AGVs and AMRs. By detecting even the most complex objects in 3D space with a small blind zone, customers are able to reduce costly accidents while ensuring highest safety in any industrial environment”, says Alexander Rudoy, CTO and Co-Founder of Toposens GmbH.

The TPU DK offers multiple communication interfaces for flexible deployment, provides a user-friendly GUI and operates on a very low power consumption of less than five watts. Further information can be obtained on TPU DK product page.