Heavy-duty vehicle powertrain decarbonisation gets nearer with free piston engines

Libertine FPE, the creator of Smart Engine control technology for free piston engine generators, has secured funding to advance development of its range-extender concept for heavy duty applications.

Free piston range extender engines can offer the efficiency of fuel cells, the durability of conventional engines and achieve carbon reductions using renewable fuels. Libertine’s ‘intelliGEN’ control technology solves the free piston motion challenge, optimising combustion conditions from the first ignition cycle.

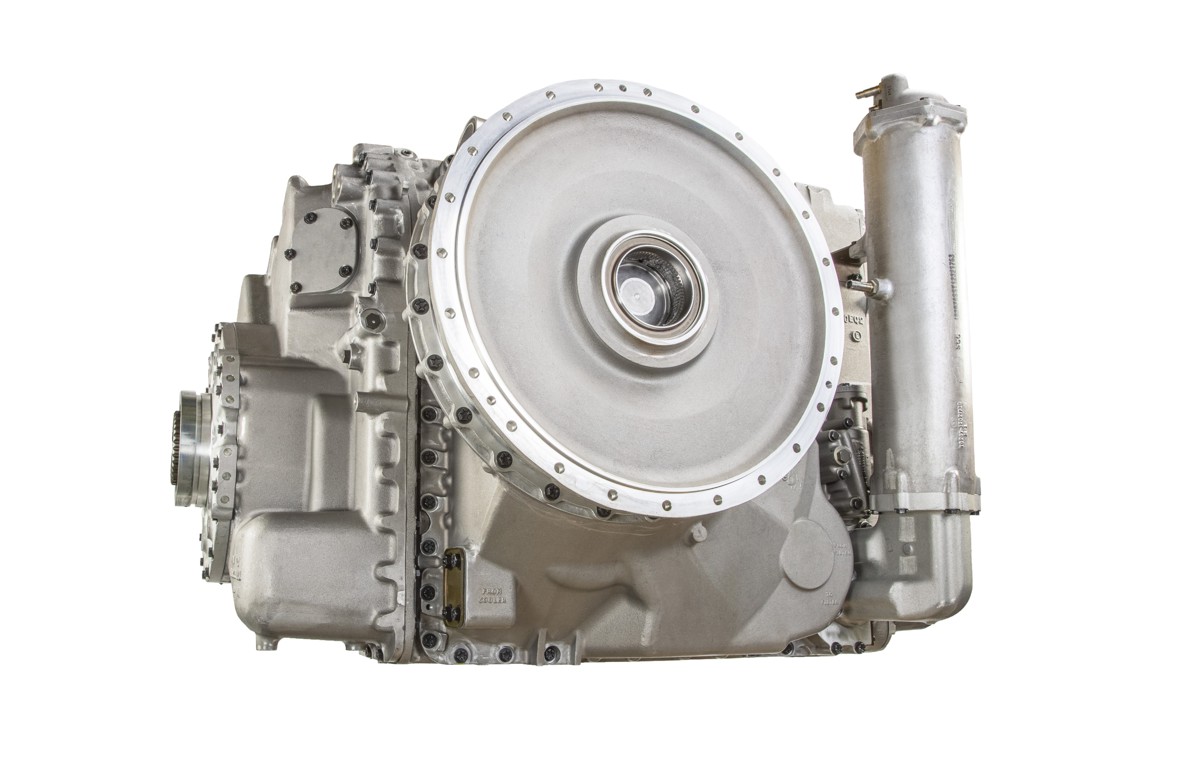

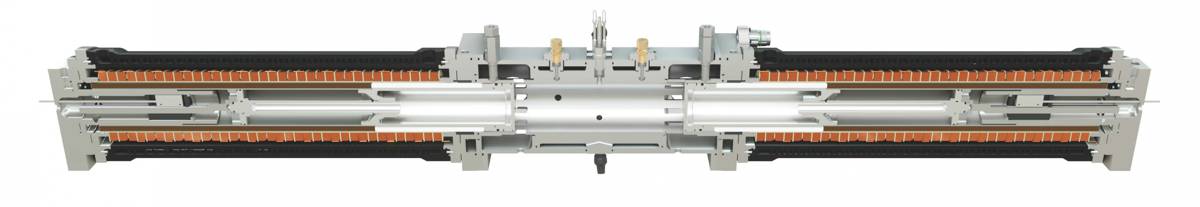

Libertine’s free piston engines contain pairs of pistons which are free to slide within a linear combustion cylinder. The introduction of a fuel mixture and a carefully timed spark drives the pistons down the cylinder where they rebound off air springs, enabling the cycle to repeat. Magnets in the pistons energise coils around the cylinder, generating electricity with an efficiency far above that of conventional engines and generators. While the FPE concept is not new, Libertine’s control and manufacturing know-how has unlocked its potential as a vehicle range extender.

Innovate UK’s Sustainable Innovation Fund is supporting the project to develop and demonstrate a performance validation prototype, building on successful proof of concept testing completed in 2020. “This win is a step forward for the UK’s ambition to reach net zero across all sectors by 2050,” says Sam Cockerill, Libertine’s CEO. “Innovate UK clearly acknowledges the strength of our technical and commercial proposition – that better engines for renewable fuels will play an important role alongside battery electrification in the UK’s roadmap to net zero.”

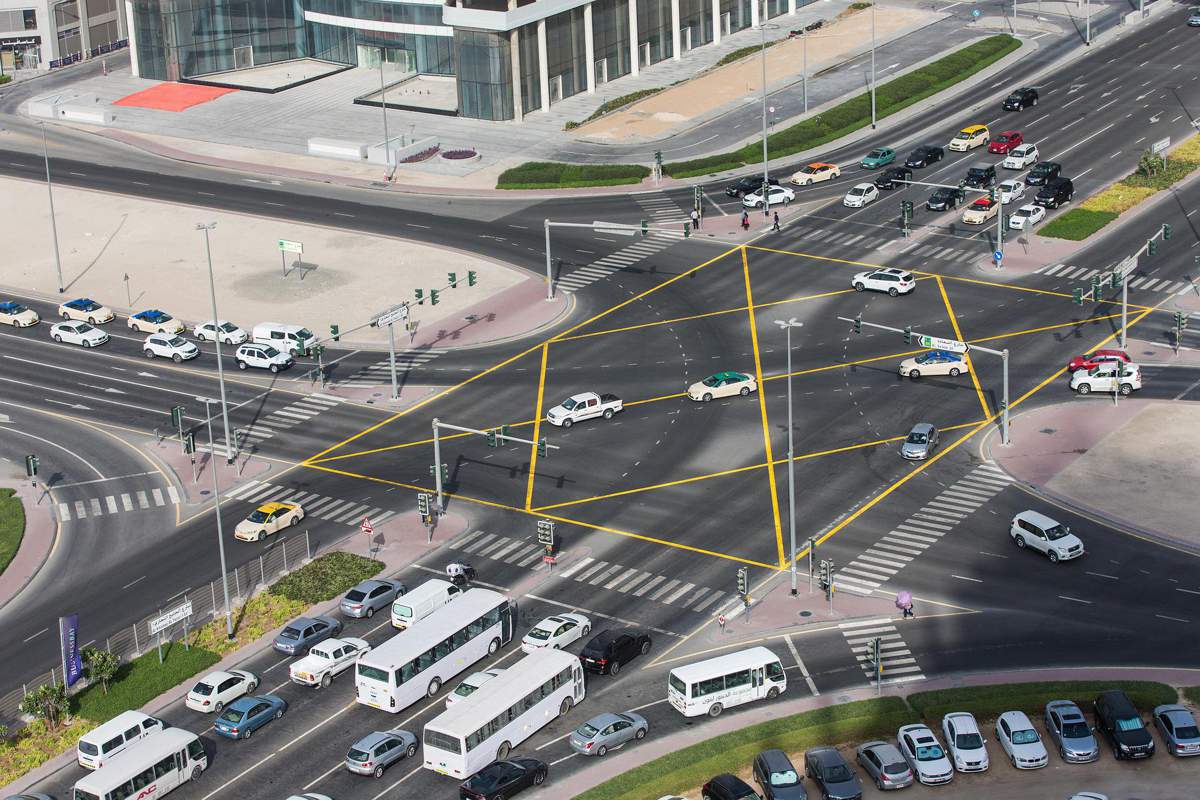

Cockerill states that the move to decarbonise heavy duty transport must be driven by demand and affordability: truck operators will not invest in zero-emission technologies if there is no effective way to run, refuel and recharge them. “As a director of a major haulier, I have first-hand knowledge of the hurdles the industry faces in reducing emissions. The impact of a pure electric powertrain on payload, productivity and up-front costs, combined with limited charging infrastructure and restricted new vehicle choice, are real challenges. The combination of a smaller battery and an efficient onboard generator using 100% renewable fuels has the potential to solve these pain points and drive significant uptake of net zero trucks before the end of the decade.”

Discussions with prospective OEM customers identified the need for a performance validation prototype as a key development milestone. The 2021 development will integrate Libertine’s technology with MAHLE Powertrain’s pre-chamber ignition system to form a multi-cylinder opposed Free Piston Engine, optimised and calibrated to start and run cleanly on renewable alcohol fuels. The project will also integrate multiple enhancements for thermal management, durability and electrical power conversion efficiency, enabling performance validation against OEM-specified requirements.

“This validation phase is ideally matched to MAHLE Powertrain’s design and development capabilities,” says Adrian Cooper, MAHLE Powertrain’s head of new technology. “In a world-first we will be integrating our passive prechamber combustion hardware and control systems with Libertine’s free piston platform, and then validating the performance of this novel architecture under load conditions and duty cycles representative of real-world operation.”

The project is the second phase of development to be funded through Innovate UK’s Sustainable Innovation Fund Competition which supports organisations to develop and demonstrate new products which help the UK’s clean growth-led recovery from the coronavirus (COVID-19) pandemic and accelerate UK’s transition to net zero.